Sammipack Rotary type granule packing machine is a high-precision automatic granule packing machine, directly supplied by China Manufacturer, suitable for tea, food, granule medicine, seeds, hardware and other industries.The machine supports automatic metering, sealing and bag cutting, combining high efficiency, ease of operation and stability to be a reliable factory-grade packaging solution.

As Sammipack Supplier, Rotary type granule packing machine is specially designed for high efficiency and multifunctional packaging requirements, which can meet the packaging requirements of different scenarios such as factories, tea shops and food processing plants.The equipment adopts microcomputer control system and photoelectric detection technology, high precision, fast speed, significantly improve packaging efficiency, reduce labor costs.

Rotary type granule packing machine China Manufacturer direct supply, has many years of OEM production experience, equipment through strict quality testing, to ensure that each machine can reach high standards of performance before deliveryWhether it is mass production or small series customization, reliable solutions are available.

High-precision measurement: accurate weight control of each package, reduce errors, improve product consistency.

Fully automatic operation: from bag making, measuring, filling to sealing completed at one time, saving manpower.

Adaptability: can pack different size, material bags, including plastic bags, aluminum foil bags, roll film bags.

Easy to operate and maintain: the equipment is clean and easy to maintain, equipped with detailed operation manual and video guidance.

Reliable after-sales service: provide professional engineer support, one-year warranty, life-long maintenance service.

High degree of automation: realize the integrated production from bag preparation to particle filling and sealing, suitable for large-scale production.

Diversified packaging adaptability: can be packaged according to customer needs of different specifications, shapes and materials of bags.

Accurate metering and high efficiency: filling weight can be accurately controlled to ensure consistency of particles in each bag.

Advanced sealing technology: back seal design and positioning cutting technology, sealing beautiful and durable.

Environmental protection and safety: automation reduces human contact and avoids pollution and oxidation.

Flexible combination: can be used alone, can also be combined with other Sammipack equipment to form a fully automatic production line.

| Item | Specification |

| Model | SM-FZ-70 |

| Automation Level | Fully Automatic |

| Voltage | 220V |

| Power | 200W |

| Bag Size (Tea Bag) | 60 × 70 mm (customizable) |

| Film Thickness | 0.5–0.8 mm |

| Bag-Making Width | Finished width 8 cm (roll width 16 cm) |

| Bag-Making Length | 0–9 cm (adjustable), up to 12 cm customizable |

| Filling Precision | ±0.2 g |

| Dimension | 430 × 510 × 1400 mm |

| Weight | 90 kg |

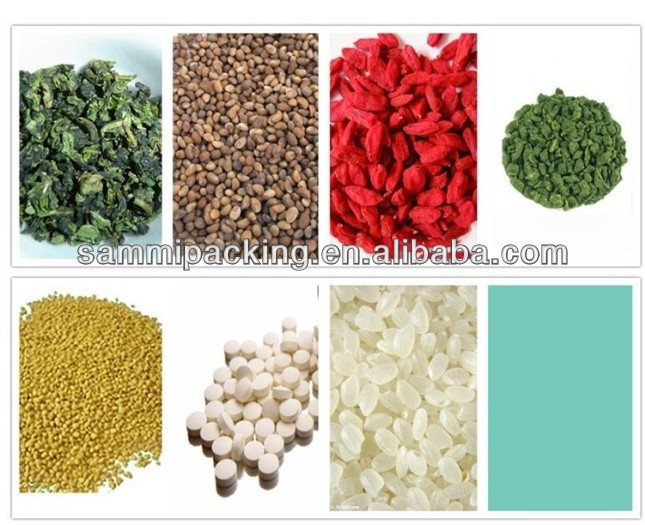

Tea packaging: tea, green tea, scented tea and other tea particles automatic packaging.

Food processing: candy, nuts, dried fruit, spices, coffee powder, etc.

Pharmaceutical industry: granular medicine, Chinese herbal pieces, health care products granular packaging.

Seed packaging: crop seeds, flower seeds and other particle packaging.

Hardware and electronic components: small screws, electronic components particles automatically measured packaging.

Suitable for bags of different materials, such as plastic bags, aluminum foil bags, roll film bags, filling volume 1- 25g (customizable 1- 50g), finished bag width 16cm, adjustable length 0- 12cm.

1.Equipment start-up: power on, set the required bag length, measuring weight.

2.Automatic bag-making: the machine automatically makes bags from rolls and positions them.

3.Metering and filling: microcomputer-controlled precise metering of particles or powders.

4.Sealing and cutting: back sealing technology cutting molding, sealing firm and beautiful.

5.Finished product output: finished product bag automatic output, convenient follow-up packaging or transportation.

Cleaning: wipe the body and bag parts with clean cloth after daily use.

Lubrication: check the mechanical moving parts every week and refuel properly.

Detection: Regularly check sensors and electronic control systems to ensure accuracy.

Spare parts: equipped with spare parts, equipment failure can be quickly replaced.

Sammipack Rotary type granule packing machine supports a variety of sample packing:

tea granule bag

Candy or nut pouch

Chinese medicine granule or powder packaging

Hardware accessories packaging

All sample bags can be customized according to customer needs size and material, to ensure beautiful and practical.

Express: DHL, FedEx, UPS, EMS, TNT, etc.

Large orders: sea or air freight option.

L/C

T/T

West Union

Escrow

PayPal

MoneyGram

Our Services

Inquiry response within 24 hours.

Each machine tested before delivery.

1-year warranty with lifetime technical support.

Professional engineers and after-sales team.

English-speaking sales team for smooth communication.

Are you a factory or trading company?

We are a professional manufacturer with our own factory.

How do you guarantee machine quality?

All machines are strictly tested and inspected before shipment. Quality stability is our core principle.

What if we don’t know how to operate the machine?

We provide an operation manual and installation videos. Our engineers and after-sales team are always available for technical support.

How can I choose the right machine?

Based on your product, bag type, weight range, and capacity requirements, we will recommend the most suitable solution.

What is the delivery time?

Standard machines are usually shipped within 1–3 days. Customized machines require additional production time.

How are broken parts handled?

Please provide photos or videos. After confirmation, we will send free spare parts within the warranty period and offer technical guidance.

Rotary type granule packing machine by Sammipack is the good solution for manufacturers and suppliers seeking high-quality, efficient, and reliable packaging machines. Whether for tea, food, pharmaceutical, or industrial granules, this China Manufacturer ensures superior performance, ease of operation, and long-term after-sales support.