Double head liquid filling machine is the preferred automation equipment for many factories to expand production capacity. It is suitable for all kinds of liquid filling needs in food and beverage, daily chemical, pharmaceutical and other industries. Whether it is a water agent, a low viscosity liquid, or a fluid with a small amount of particles, the equipment can achieve high precision filling and play a stable and reliable role in the production line. With the increasing requirements for efficiency, hygiene and compliance in factories around the world, Sammipack double-head liquid filling machines from China Manufacturer, Supplier and Factory have won wide application in many countries due to their precise structure, high quality materials and excellent cost performance.

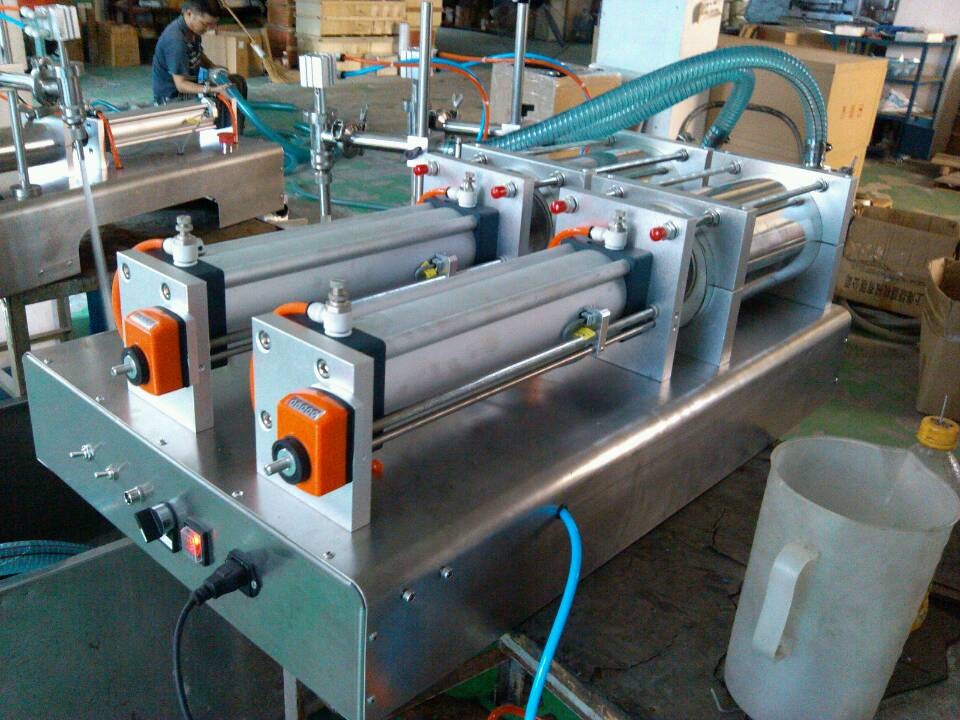

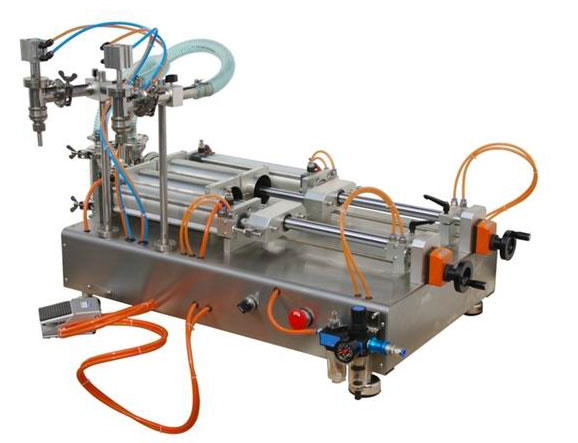

Developed and manufactured by Sammipack, this double head liquid filling machine is a high-precision double-head filling machine for the global market. Double synchronous filling structure is adopted. The whole machine is made of pneumatic drive and food grade stainless steel. It is suitable for filling all kinds of liquid products. As a professional Chinese liquid filling machine manufacturer & supplier, Sammipack factory continuously optimizes mechanical performance to ensure high efficiency, stability and durability of equipment, which can meet the batch filling requirements of food factories, daily chemical enterprises, pharmaceutical workshops, chemical enterprises and other different scenarios, especially suitable for buyers with high requirements for filling efficiency and filling accuracy.

Double-head liquid filling machines play a key role in a variety of industries, covering almost all areas requiring liquid packaging:

1. Food and beverage industry

Mineral water, fruit juice, beverage filling

Filling of sauces and condiments (such as soy sauce, edible oil and vinegar)

Filling of dairy products (e.g. milk, yogurt)

Its food-grade construction and high-precision filling capabilities significantly improve packaging hygiene and

consistency.

2. Daily chemical products industry

Shampoo, shower gel, hand sanitizer

Cosmetics (toner, lotion, etc.)

Suitable for daily chemical liquids with good fluidity, low viscosity or slight viscosity.

3. Chemical industry

Disinfectants, detergents, solvents

Low viscosity chemical liquid filling

It can adapt to certain corrosive liquids and adopts corrosion resistant 304/316 stainless steel.

4. Pharmaceutical and medical industries

Oral liquid, alcohol, medical solvent

Production and material selection are carried out in strict accordance with GMP standards.

(1) Double-effect parallel, capacity multiplication_solve the bottleneck of enterprise capacity

Compared with single-head filling machine, double-head synchronous filling efficiency is increased by 80%-120%, and 10~35 filling times can be completed per minute (taking water as an example), which is very suitable for factories with large order volume and tight delivery.

The factory can increase production in limited space without adding multiple single-head equipment.

(2) Accurate filling, zero waste--reduce liquid loss and improve pass rate

Filling error ≤ ±1%

Precision pneumatic piston system controlled by five-way valve

Special anti-drip and anti-wire drawing structure

Adapt to water, essence, sauce, solution, chemicals and other different liquids

Effective solution:

✔ Large manual filling error

✔ High percentage of waste materials

✔ Different batches of product capacity

✔ The filling qualification rate can be increased to more than 99.8%.

(3) Reduce labor costs and reduce maintenance pressure-saving long-term operating costs for enterprises

One employee can fill both ends

Pneumatic drive design, simple structure, stable and durable

Key components adopt German FESTO or Taiwan AirTAC, high life and low failure

Compared to manual filling or old-fashioned equipment:

✔ Save on staffing

✔ Extended device life

✔ Reduce downtime costs

(4) Meet food grade and GMP standards_comprehensively improve corporate hygiene compliance

304/316L stainless steel contact materials

No pollution, easy to clean

Meet the hygiene requirements of food and drug industry

Effectively address the risk of cross-contamination caused by manual filling.

(5) Compact structure, easy operation and maintenance

Desktop design, small footprint

Easy adjustment (flow, speed, stroke can be adjusted according to demand)

Comes with instruction manual and video

Suitable for factories of all sizes. Get started quickly from scratch.

The equipment uses cylinder driven piston, through the five-way valve to control the flow of materials, so as to achieve accurate filling. The stroke is controlled by magnetic switch, which can adjust the filling volume flexibly. The filling head is equipped with anti-drip device to ensure high precision and cleanliness.

Germany FESTO/Taiwan AIRTAC Pneumatic Components

304/316L stainless steel material contact parts

Easy adjustment, compact structure

Drip-proof, anti-stretch, lift-off filling head

High precision flow control system

| Model | G1WY-2Y-100 | G1WY-2Y-300 | G1WY-2Y-500 | G1WY-2Y-1000 | G1WY-2Y-3000 | G1WY-2Y-5000 |

| Filling Range | 10–100 ml | 30–300 ml | 50–500 ml | 100–1000 ml | 300–3000 ml | 500–5000 ml |

| Filling Speed | 10-35 times/min (using water as an example) | |||||

| Air Pressure Requirements | 0.4–0.6 MPa | |||||

| Filling Accuracy | ≤ ±1% | |||||

| Machine Dimensions (mm) | 806×180×690 | 880×230×665 | 880×230×665 | 1065×230×665 | 1250×400×300 | 1390×420×380 |

| Machine Weight (Kg) | 30 | 35 | 40 | 45 | 60 | 80 |

We support OEM customization, and can select the appropriate model based on the customer's product, packaging, and flow rate requirements.

After using the double-head filling machine:

Single line capacity increased from 800 bottles to 1600 bottles/hour

90% reduction in sauce dripping rate

Staff costs reduced by 1/2

Filling hand sanitizer, shampoo, etc.:

More uniform fill volume

No drawing, no dripping

Clean bottle mouth, no manual wiping

Meet sanitary requirements

Effectively reduce cross-contamination

Suitable for multi-variety, small batch switching frequent production mode.

1. Are you a real China Factory?

Yes, we are a physical factory located in Dongguan, Guangdong Province, brand name Sammipack, with more than 15 years of

export experience.

2. How is the quality of your Double head liquid filling machine?

All equipment must pass strict machine test and filling test before leaving the factory, and use durable pneumatic

components and food-grade stainless steel materials for strong stability and long life.

3. What if I can't operate it?

Provide:

Operating manual

Installation & Commissioning Video

7×24 Technical Support

Novices can pick it up quickly.

4. How to choose the right model?

You only need to provide:

Item Type

Filling capacity range

manufacture requirement

We can recommend the most suitable model for you.

5. How long is the lead time?

Standard model 1~3 days shipment;

Custom models 3 to 7 days depending on requirements.

6. What if the parts break?

During the warranty period, we provide free accessories and provide remote technical support.

15+ years of experience in equipment production, serving global customers

Export to Europe, America, Southeast Asia, Middle East countries

Long-term cooperation with food factories, daily chemical factories and pharmaceutical factories

Reasonable equipment price, stable performance, timely after-sales

Support OEM customization and mass production requirements

We are not only China Manufacturer, Supplier, Factory, but also a trusted long-term partner of many overseas buyers.

if you're looking for a

✔ Increase production capacity

✔ Control costs

✔ Guaranteed accuracy

✔ Meet hygiene requirements

Sammipack's double-head liquid filling machine will be a very cost-effective choice.

It is suitable for filling from food to daily chemical, from chemical to pharmaceutical multi-industry needs, is the

global buyers, factories, distributors trusted filling machine equipment.