Semi automatic cream filling machine is suitable for quantitative filling of cosmetics, condiments, detergents and other pastes and high viscosity liquids, which can significantly improve filling accuracy and reduce material waste. Many factories are most concerned about performance stability, operational difficulty and cost input when selecting equipment. In fact, finding the right balance is not difficult. This series of equipment supports quantitative filling, simple operation, compatible with a variety of materials, stable and durable structure, and has a friendly price range, very suitable for small and medium batch production.

Semi automatic cream filling machine is a semi-automatic filling machine developed by Sammipack for small and medium-sized production lines such as cosmetics factory, seasoning factory, daily chemical factory and pharmaceutical factory. As a professional China Manufacturer, Supplier & Factory, Sammipack has more than 15 years of export experience, and its products are exported to European, American and Asian markets. We always insist on providing reliable quality, reasonable price, friendly operation and convenient maintenance of filling equipment.

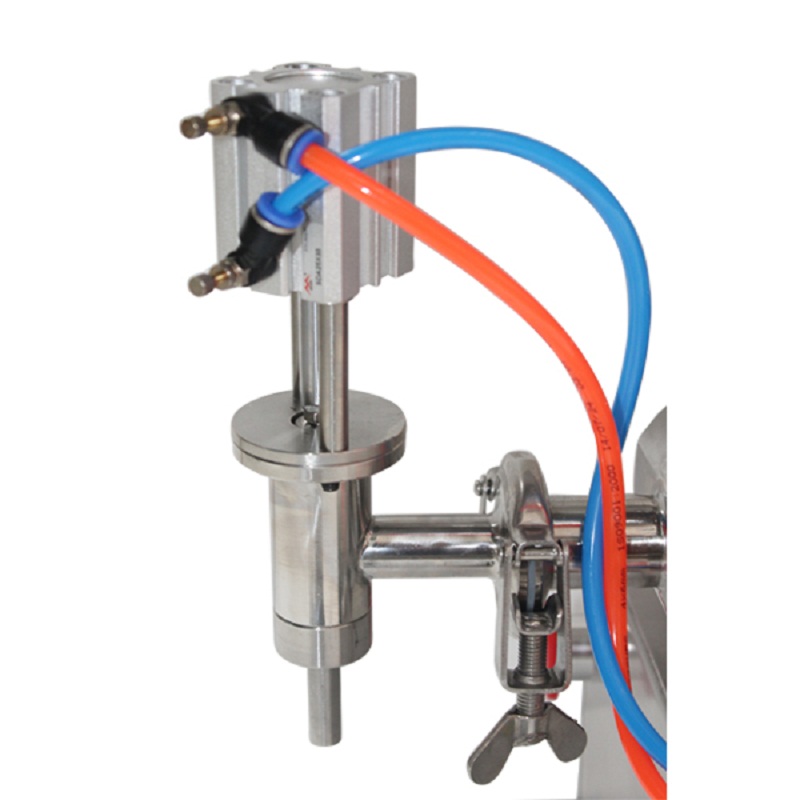

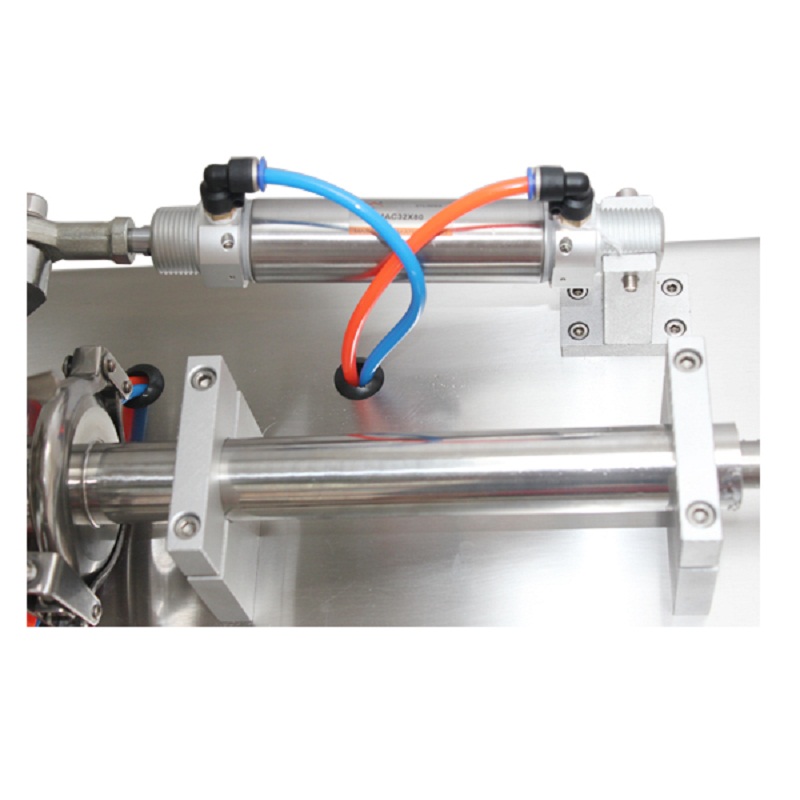

This series of filling machine adopts pneumatic piston type quantitative system, combined with five-way valve material path structure, can stably process a variety of materials from low viscosity liquid to high viscosity paste, especially in anti-drip, anti-drawing, accurate quantitative performance outstanding, very suitable for foreign trade processing plants, OEM factories and fast-moving consumer goods factories that need stable capacity.

Adopt pneumatic drive structure, rapid response, stable filling speed.

The single-head machine is capable of 10 ‰ 35 fills per minute (water, for example).

and that specification change is simple, and the adjustment can be complete only by adjusting the scale, without complex operation.

No power supply is needed, and the pneumatic power is safer and more stable.

Scenario:

Suitable for small and medium-sized batch production, trial production workshop, e-commerce processing, small brand fast supplement.

Results:

Replace manual filling, at least 4 - 8 times more efficient

Reduce human error and improve consistency

24-hour continuous and stable operation

A piston type quantitative structure is adopt, and that metering error is control to be +/-1%.

Equipped with anti-drip, anti-drawing structure, to avoid contamination of the bottle or waste of materials.

The filling quantity can be adjusted at will, which is very suitable for multi-specification products.

Applicable materials include:

Cosmetics: face cream, facial cleanser, hand cream

Food: sauces, honey, peanut butter

Daily chemical products: laundry detergent, vehicle lubricating oil, detergent

Chemicals: grease, gel, raw material paste

Results:

Maximize material usage

Higher consistency of finished products

Adapt to multi-category filling requirements and reduce equipment acquisition cost

The body is made of 304L stainless steel, which is corrosion resistant and meets GMP requirements.

The key pneumatic components are imported brands such as AirTac and FESTO, which have longer stable life.

Compact structure, small footprint, suitable for factories, studios, laboratories and other scenes.

Value of Results:

Low failure rate and low maintenance cost

long-term stable operation

More suitable for export-oriented customers and high-standard customer groups

Operation video and instruction manual are included

Filling volume and speed can be adjusted by knob

Easy to remove and clean in minutes

Value of Results:

New employees can be hired quickly

Reduce training costs

Easier maintenance

The Semi automatic cream filling machine uses pneumatic piston filling systems of the GFA series:

the reciprocate motion of that piston is driven by the cylinder

Five-way valve to control suction and filling path

Magnetic switch to control stroke for precise dosing

Drip-proof filling head closes automatically to avoid material residue

The structure is specially designed for paste and high viscosity materials, with stable flow and accurate quantification, which can effectively improve the quality of the production line.

| Model number | G1WG-100 | G1WG-300 | G1WG-500 | G1WG-1000 | G1WG-3000 | G1WG-5000 |

| Filling range | 10–100 ml | 30–300 ml | 50–500 ml | 100–1000 ml | 1000–3000 ml | 1000–5000 ml |

| Filling speed | 10–35 cycles/minute (for water) | |||||

| Air pressure requirements | 0.4–0.6 MPa | |||||

| Filling accuracy | ±1% | |||||

| Body material | 304L Stainless Steel | |||||

| Machine dimensions | 806×180×690mm | 880×230×665mm | 880×230×665mm | 1065×230×665mm | 1250×400×300mm | 1390×420×380mm |

| Machine weight | 30kg | 35kg | 40kg | 45kg | 60kg | 80kg |

Special filling ranges, hoppers, heating devices, and stirring devices can be customized according to customer requirements.

Suitable for quantitative filling of facial cream, body lotion, facial cleanser, essence gel and other products, which can effectively avoid pollution to the bottle mouth.

Such as butt, sauce, honey, jam, salad dressing and that like, and meet the requirement of food hygiene.

Laundry detergent, car lubricants, glass water, ointment and other products more smoothly.

Suitable for filling viscous chemical raw materials, pastes, and sealants.

It can fill over 85% of paste and high-viscosity materials.

It uses a large-diameter piston structure with a smooth flow path, virtually eliminating clogging; for extremely high-viscosity materials, heating or stirring mechanisms can be added.

Yes, pneumatic piston with five-way valve structure, so that the filling volume repeatability is very high, the accuracy can be stable within ±1%.

Very good. The operation of the device is very simple:

Insert air pipe

Adjust fill volume

Start production with foot pedal or automatic mode

In addition, Sammipack provides video teaching and after-sales technical support.

The machine adopts imported pneumatic components and 304L stainless steel structure, can work continuously for 24 hours; low failure rate, suitable for long-term factory use.

We are Dongguan Sammi Packing Machine Co., Ltd.,

More than 15 years of export experience, mainly exported to Europe, America and Asia.

Each machine undergoes QC inspection and actual filling tests.

Free delivery of accessories within the warranty period;

Spare parts are provided at Factory cost outside the warranty period.

Delivery time: 1 - 3 days for spot models; 3 - 7 days for customized models

Payment: T/T, L/C, PayPal, Western Union, Credit Card, Trade Assurance

Packing: Export standard wooden case/honeycomb cardboard box

Mode of transportation: sea, air, express (DHL / FedEx / TNT / Aramex / EMS)

Shipping time limit:

Express: about 5 days

Air: approx. 7 days

Ocean: 15 - 30 days

As a professional China Manufacturer & Supplier, Sammipack offers a complete filling solution:

More than 15 years manufacturing experience

Stable cooperation with thousands of customers

Factory direct supply price, support OEM

CE certification

Rapid after-sales response

Supports custom functions, molds, hoppers, mixing, heating configurations

Our goal is to make our customers 'production more efficient, more stable and more economical.

The Semi automatic cream filling machine is known for its high accuracy, high stability, reliable construction and price friendliness, making it ideal for production enterprises that are looking for cost performance and reliability. Whether you're a brand, a processor, a trader or an OEM plant, the machines are a competitive choice for the paste filling industry by providing consistent, efficient and sustainable filling capabilities.

For more appropriate models, customizations, please feel free to contact our Sammipack factory team.