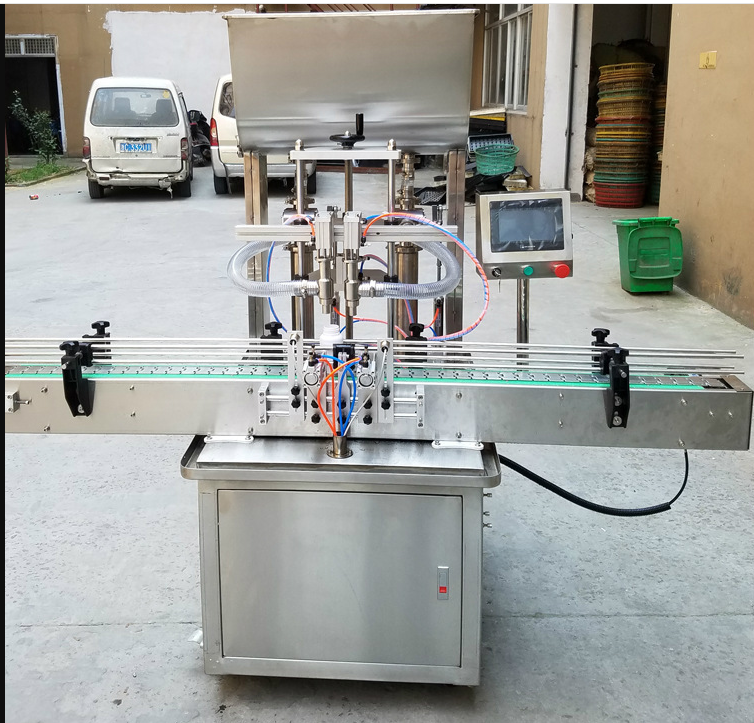

As China professional packaging machinery Manufacturer & Supplier, Sammipack is committed to providing efficient, accurate and stable filling solutions for food, daily chemical, pharmaceutical and chemical industries. Among them, the 2 Heads Automatic Cream Paste Filling Machine has been highly recognized in the global market for its excellent automation capabilities, high precision filling performance, comprehensive compatibility and superior durability.

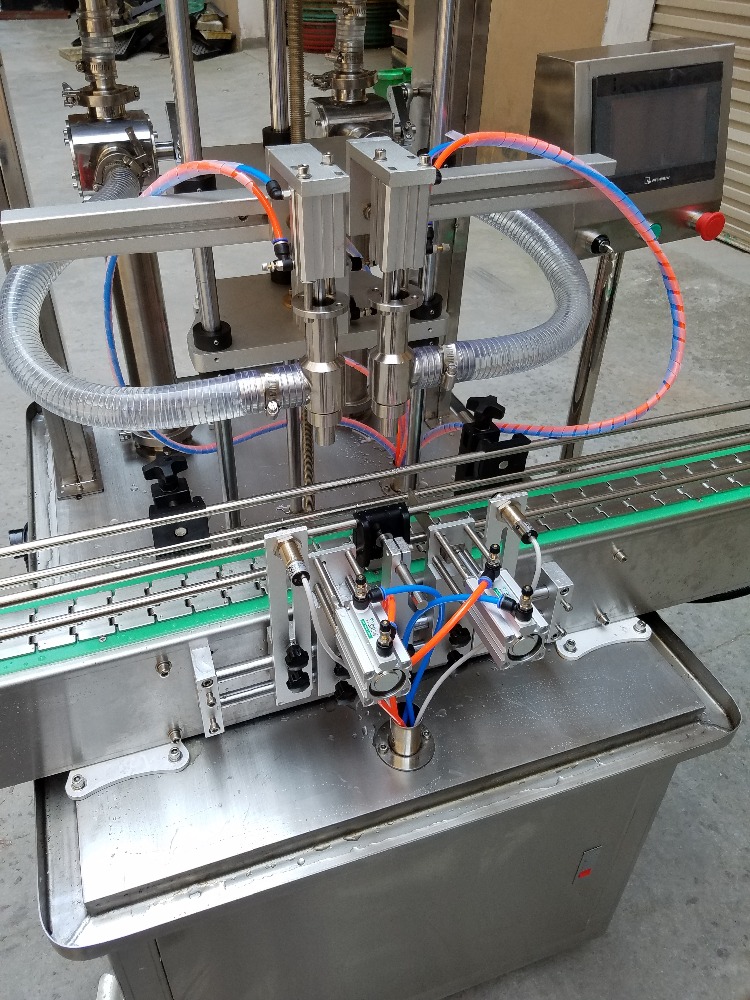

2 Heads Automatic Cream Paste Filling Machine adopts advanced PLC automatic control system to realize continuous automatic process from bottle positioning, quantitative filling to conveying output, greatly improving production efficiency and significantly reducing manual participation. It is the core efficient filling equipment in many factory production lines.

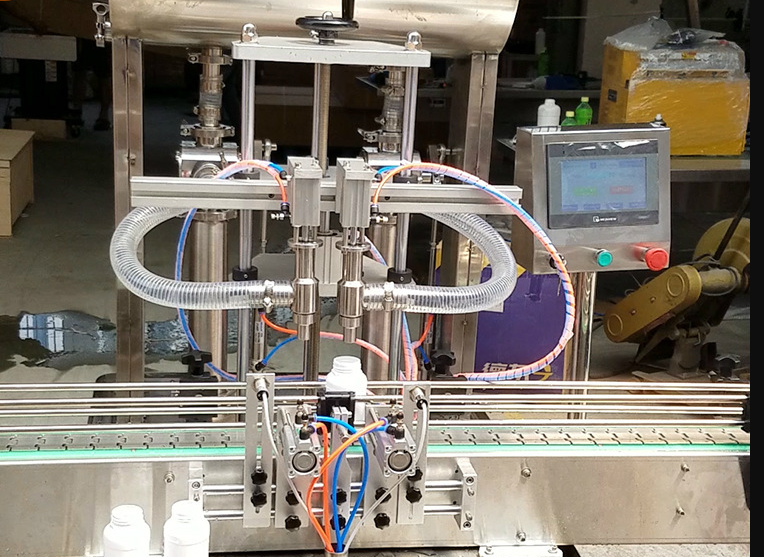

2 Heads Automatic Cream Paste Filling Machine equipped with precision servo drive system and high sensitivity flow control module, intelligently adjust filling curve according to different paste characteristics, realize:

Error ≤±1%(liquid)/≤±2%(paste)

Filling speeds up to 10 - 30 bottles/min

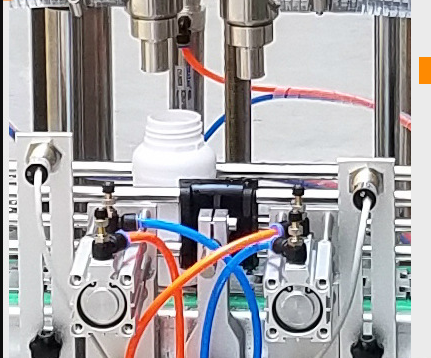

High sealing anti-drip filling head, effectively avoid contamination of the bottle

Anti-foam function, reduce the defective rate caused by bubbles

Suitable for high value-added products such as honey, cream, nut butter, jam, etc., ensuring brand consistency and end image.

As a highly integrated automatic filling machine, this 2 Heads Automatic Cream Paste Filling Machine achieves:

Automatic bottle feeding → automatic positioning → double head synchronous filling → automatic output

1 - 2 people can manage the entire production line

24-hour stable operation to meet peak season capacity requirements

With Sammipack production of labeling, capping, sealing, packing equipment can achieve the whole line linkage, maximize production efficiency.

This equipment is widely used in:

Food industry: jam, honey, sesame paste, tomato paste, meat sauce

Daily chemical industry: skin cream, mask mud, hair mud

Chemical industry: coating glue, grease, cleaning paste

Pharmaceutical industry: ointment, suppository paste, etc.

Suitable for high viscosity, medium viscosity and granular pastes.

All parts in contact with materials shall adopt:

304 or 316L Stainless Steel

Food grade sealing ring

Corrosion resistant high temperature resistant design

Ensure cleanliness, safety, durability and meet the stringent hygiene standards of the food and pharmaceutical industry.

| Project | Specifications: |

| Number of filling heads | 2 Heads (Expandable to 4/6/8 Heads) |

| Filling range | 10–100ml, 30–300ml, 50–500ml, 100–1000ml, 1000–2500ml, 1000–5000ml (Select according to model) |

| Production speed | 30–50 bottles/minute (20–40 bottles/minute for high-viscosity materials, depending on material fluidity) |

| Filling accuracy | Liquid ≤±1%; Paste ≤±2% |

| Applicable material viscosity | 1,000–300,000 cps (Supports high-viscosity and particle-containing pastes) |

| Air pressure requirement | 4–8 kg/cm² (Slight variations depending on the model) |

| Operating system | PLC + 7-inch Touch Screen (Switchable between Chinese and English) |

| Power source | Servo motor drive / Pneumatic control combination |

| Anti-drip system | Pneumatic back-suction advanced anti-drip structure |

| Control method | Fully automatic mode / Single filling mode / Continuous filling mode |

Touch screen operation interface, parameter visual settings, support Chinese and English bilingual menu.

No bottle, no filling, avoid waste and splash.

Filling speed and capacity can be adjusted automatically by program, or can be adjusted independently by single head.

Pneumatic suction structure, clean finish without wire drawing.

It can be disassembled without tools, suitable for factories with frequent material replacement.

Adapt to different production capacity configuration, can be extended to the whole line automation plant.

| Model | Machine Dimensions (L×W×H) | Machine weight: | Air source interface | Power Requirements: |

| SM-100-2Y | 1200×650×1500mm | 450kg | Ø10mm pipe | AC 220V / 50Hz |

| SM-300-2Y | 1200×650×1500mm | 460kg | Ø10mm pipe | AC 220V / 50Hz |

| SM-500-2Y | 1250×680×1580mm | 470kg | Ø10mm pipe | AC 220V / 50Hz |

| SM-1000-2Y | 1350×700×1600mm | 500kg | Ø12mm pipe | AC 220V / 50Hz |

| SM-2500-2Y | 1450×750×1650mm | 530kg | Ø12mm pipe | AC 220V / 50Hz |

| SM-5000-2Y | 1600×800×1700mm | 550kg | Ø12mm pipe | AC 220V / 50Hz |

Food Factory Bulk Filling Scenarios

Jam, honey, sauce factory in the peak season orders a lot, variety, frequent switching production line, and this equipment supports fast production change, accurate filling, help the factory shorten delivery time.

Clean Filling Scenarios in Cosmetic Factory

Cream production requires high hygiene level. The machine is made of food-grade 316L material and is designed with closed hopper to ensure safety and no pollution.

Quantitative Packaging Scene of Chemical Paste

Such as grease, chemical paste, need high stability, corrosion resistance, long-term operation of the equipment, the machine low noise, stable structure, very suitable.

1. What is the filling accuracy of this 2 Heads Automatic Cream Paste Filling Machine?

The accuracy can be kept within that range of less than or equal to plus or minus 1 percent for liquid and less than or

equal to plus or minus 2 percent for paste, and a servo system and a flow control algorithm are adopt to ensure

consistency.

2. Is it suitable for materials containing particles?

Very good. The machine is equipped with large diameter filling valve, suitable for paste materials containing fruit, nut

pieces and seasoning particles.

3. Is it convenient to clean?

The whole machine adopts quick-release structure, which can remove the pipeline without tools, which is very suitable

for factories with multiple materials switching.

4. Can I connect it to an automated production line?

Very good. It can be seamlessly connected with Sammipack labeling machine, capping machine, inkjet printer and box

packing machine to realize fully automatic whole line.

5. Is customization supported?

Multi-dimensional customization of filling range, number of filling heads, hopper size, conveyor belt length, etc.

6. Does the manufacturer provide after-sales service?

As a professional Manufacturer & Factory in China, Sammipack offers:

whole-process technical guidance

video teaching

Lifetime Technical Support

Complimentary parts (during warranty period)

15+ years of export experience, recognized by global customers

products have passed CE certification

Professional QC inspection to ensure stable operation of the machine

Services in the United States, Europe, Asia and more

Substantial cash, fast shipping 1 - 3 days

Strong OEM customization capabilities

2 Heads Automatic Cream Paste Filling Machine is a high-end filling machine with speed, precision, automation ability and durable quality, which is suitable for quantitative filling of high viscosity materials in many industries such as food, daily chemical industry, medicine, chemical industry, etc. Reliable performance, intelligent control systems, and a highly hygienic structure significantly increase productivity, reduce labor costs, and help factories build more modern, efficient, and sustainable production lines.

If you are looking for high quality filling equipment from a professional Manufacturer/Supplier in China, Sammipack is the safe choice.