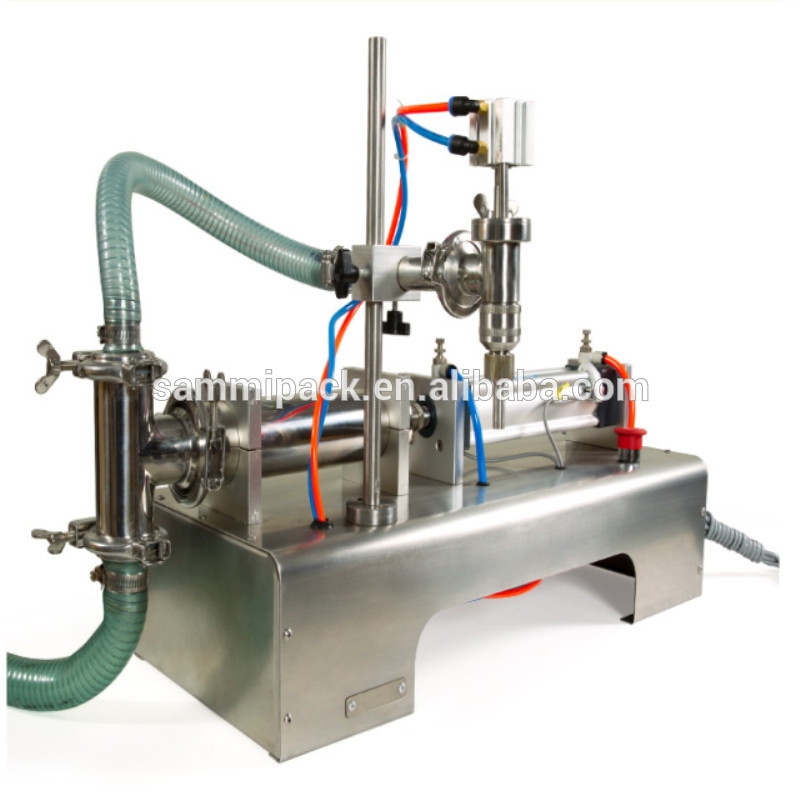

Semi automatic liquid filling machine is a pneumatically driven high-precision piston filling machine, which is widely used in daily chemical, food, pharmaceutical, chemical and other industries, and can be applied to various liquids such as washing liquid, fragrance, water, alcohol, disinfectant, oil, oral liquid, etc. The equipment has the characteristics of high stability, low energy consumption, convenient maintenance, simple operation, etc. As a professional Manufacturer, Supplier and Factory from China, Sammipack provides global customers with highly reliable filling equipment and one-stop liquid packaging solutions through strict quality control and rich export experience.

Semi automatic liquid filling machine from Sammipack, pneumatic control, internal core structure of high-precision piston and three-way valve system, enabling fast, controllable and accurate liquid filling.

The whole machine has compact structure and is made of 304/316L stainless steel, which can meet the requirements of food grade and GMP production environment. It is designed to increase production capacity, reduce material waste, reduce labor costs, and enable enterprises to achieve stable and reliable production efficiency at lower costs. It is ideal for small factories, medium factories and laboratory production lines.

Filling speed of 0.5 - 2 seconds per bottle

Daily capacity of 8000 - 20000 bottles per unit

Low pneumatic drive energy consumption, only 0.3 - 0.8 kW/h

300 - 500% increase in yield compared to manual filling and higher stability

Enterprises can quickly improve production capacity, especially suitable for factories with high production season and fast order growth.

High precision pneumatic valves and stable piston systems

Batch consistency is strong, deviation is less than 0.3%

Suitable for a wide viscosity range (0.1 - 10000 mPa·s)

Whether it is a water agent, oil, or a daily chemical liquid with microviscosity, it can ensure the same filling amount and reduce rework and material waste.

Fillable materials include (but are not limited to):

Laundry detergent, hand sanitizer, car wash

Edible oil, vegetable oil, sauce

Alcohol, disinfectant

Liquid medicine, oral liquid, nutritional supplement

Toilet water, fragrance liquid

Coating agent, pesticide, chemical liquid

Cosmetics essence, perfume, skin lotion

Applicable to food factories, cosmetics factories, pharmaceutical factories, chemical plants, e-commerce packaging factories, laboratories, etc.

Anti-drip, anti-drawing, diving filling structure, can prevent:

End of filling liquid drawing

high foam material splash

Production line contamination

Especially suitable for high foaming products (such as detergent, disinfectant, etc.).

full pneumatic control

No motor design

Can be used in areas with electrical safety requirements

It is safer to use in alcohol, solvents and other environments.

Suitable for production:

hand sanitizer

laundry detergent

softener

detergent

disinfectant

Suitable for multi-SKU, small batch, multi-specification flexible production.

Fillable:

Seasoning sauce

Edible oil

Fruit juice

Esters

Syrup

Food grade stainless steel is adopted, which meets the requirements of food production.

Applicable:

Liquid medicine

Oral liquid

Nutrient solution

Sanitizer

Compatible with GMP standards.

Suitable for:

Coating

Surface treatment liquid

Pesticide

Cleaning agent

Suitable for highly corrosive materials, optional 316L steel.

From manual bottle filling to stable production capacity of 10 - 35 bottles per minute, it helps enterprises to quickly improve order processing capacity.

Single equipment only needs 1 person to operate, instead of 3 - 4 manual filling workers, suitable for factory automation upgrade.

High-precision control reduces:

the rate of reworking

overfilling loss

losses due to leakage

Ensure that every drop of liquid is filled accurately.

Consistent filling volume makes the product more trusted by customers in overseas markets (such as America, Europe, Asia).

| Model | Filling Range | Machine dimensions (L×W×H) | Weight |

| G1WY-100 | 10–100 ml | 806×180×690 mm | 42 kg |

| G1WY-300 | 30–300 ml | 880×230×665 mm | 45 kg |

| G1WY-500 | 50–500 ml | 880×230×665 mm | 48 kg |

| G1WY-1000 | 100–1000 ml | 1065×230×665 mm | 52 kg |

| G1WY-3000 | 300–3000 ml | 1250×400×300 mm | 64 kg |

| G1WY-5000 | 500–5000 ml | 1390×420×380 mm | 86 kg |

Filling speed: 10 ~ 35 times/min (water as an example)

Operating pressure: 0.4 ▼ 0.6 MPa

Filling error: ±1%

Material: 304/316L stainless steel

Customizable Services: Support

Equipment Highlights:

Germany FESTO /Taiwan Airtac Pneumatic Components

Piston type three-way valve filling system

Drip-proof submerged filling head

Precise adjustment mechanism, filling speed and volume can be adjusted independently

Quick-release structure for easy cleaning

Very good. The equipment adopts high-precision piston metering mechanism, the error is kept within ±0.5 ‰ 1%, the stability is strong, and the filling requirements of food grade and pharmaceutical grade can be met.

It is suitable for water liquid to high viscosity liquid, with the range of 0.1 - 10000 mPa·s, and can be filled with oil, paste and viscous liquid.

Simple operation, provides:

Chinese and English Operation Manual

Install video

Engineer online guidance

Generally 10 minutes to master the key points of operation.

The equipment uses a pneumatic structure and does not require a motor, resulting in very low maintenance costs.

The main replacement part is the sealing ring, which has a long lifespan and low cost.

We offer:

Video Installation Instructions

Online Engineer Assistance

Fault video detection

After-sales support is available to customers worldwide.

Most models are shipped in stock within 1 - 3 days, and special fill volumes can be customized.

Products exported to America, Europe, Asia, many countries, trusted by customers.

More competitively priced, OEM/ODM support.

Professional QC, each machine is filled and tested before leaving the factory.

No matter installation, commissioning, use or troubleshooting, there are specially-assigned persons for docking.

The Semi automatic liquid filling machine is a popular solution in the field of liquid filling with high precision, high efficiency, good stability and a very good price/performance ratio. Whether you come from the food industry, daily chemical industry, pharmaceutical industry or chemical industry, Sammipack, as a professional Manufacturer and Supplier from China, provides you with reliable, durable and easy-to-maintain one-stop filling equipment.

Please feel free to contact us for a quote, specifications or video.