Double heads cream filling machine is a high efficiency, high precision and high stability machine professionally built by China High-end Packaging Equipment Manufacturer and Supplier--Sammipack. The equipment is widely used in cosmetics, food, pharmaceutical, daily chemical and other industries, is the good choice for factory batch filling of high viscosity paste.

Cosmetics industry: cream, lotion, essence, body lotion, sunscreen, matte cream, etc.

Food industry: tomato sauce, salad dressing, peanut butter, honey, sesame sauce, jam, etc.

Daily chemical industry: toothpaste, hand cream, cream detergent, shampoo (high viscosity), etc.

Pharmaceutical industry: ointment, traditional Chinese medicine cream, gel, ointment, etc.

With the dual-head synchronous filling structure, this equipment is known for its high efficiency, high precision, low failure rate and strong stability in the field of filling high viscosity materials, which is the reason why many factories choose Sammipack from China Factory.

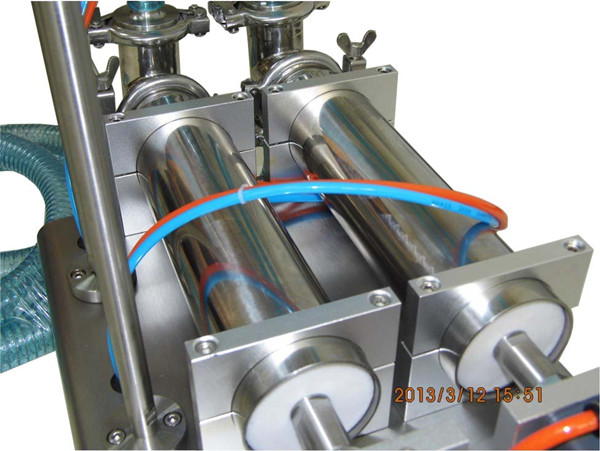

This Double Heads cream filling machine uses a pneumatically driven piston pump structure to achieve precise control of filling volume by adjusting the cylinder stroke. After the material enters the filling system through the hopper, it is sucked by the piston and pushed to the filling nozzle with high precision to ensure the consistent distribution of each bottle of material.

Double-head filling: independent or simultaneous filling, greatly improving production efficiency

Piston metering system: suitable for high viscosity pastes, high accuracy

316L Sanitary contact material: Food grade/Pharmaceutical grade Safer

Drip-proof filling nozzle: clean filling, no drawing, no dripping

Pneumatic control: smooth operation, low failure rate, long service life

Its unique structure can easily handle filling from fine paste to granular paste, which is a cost-effective choice for small and medium-sized factories to expand production capacity.

Pain point 1: low production efficiency, delayed delivery

Traditional single-head filling machines have limited efficiency and cannot cope with large orders during peak seasons.

Solution:

Dual head construction allows simultaneous operation

The capacity of a single machine is increased by about 90% compared with that of a single head

Parameter adjustment takes only 2 - 3 minutes

Fast and easy refueling and specification change

Pain point 2: large filling error, unstable quality

Older equipment errors can reach ±5%, resulting in:

Raw material waste

Weight of finished product is inconsistent

Increased number of complaints

Sammipack Equipment Advantages:

Filling error controlled within ±1%

Piston metering ensures stability and accuracy

Drip-proof nozzle prevents filling overflow

Pain point 3: high viscosity materials difficult to fill

High viscosity paste easy to block, easy to break, filling uneven.

Equipment advantages:

Special feed valve structure, smooth flow

Hopper support heating insulation (optional)

Do not pick paste: granular paste can also be poured

Pain point 4: cleaning trouble, high health risk

The old equipment structure is not disassembled or unsanitary.

Solution:

316L is used for contact parts

Quick disassembly, 5 minutes to clean

Meet the requirements of food, cosmetics and pharmaceutical production environment

High-quality pneumatic components: Germany FESTO, Taiwan AirTac

Double-head independent adjustment system: support mixed production of different filling quantities

Optional automatic suction system: reduce labor

Optional stirring/heating (suitable for honey, plaster, etc.)

Pedal + Auto Two working modes

Easy installation in small and compact factories

| Model | G1WG-2Y-100 | G1WG-2Y-300 | G1WG-2Y-500 | G1WG-2Y-1000 | G1WG-2Y-3000 | G1WG-2Y-5000 |

| Filling Range | 10–100ml | 30–300ml | 50–500ml | 100–1000ml | 300–3000ml | 500–5000ml |

| Filling Speed | 10–35 bottles/min (based on water) | |||||

| Working Air Pressure | 0.4–0.6 Mpa | |||||

| Filling Accuracy | ±1% | |||||

| Machine Dimensions | 806×180×690mm | 880×230×665mm | 880×230×665mm | 1065×230×665mm | 1250×400×300mm | 1390×420×380mm |

| Weight | 42kg | 45kg | 48kg | 52kg | 64kg | 86kg |

| Customizable | Supports customization of filling range, hopper, heating, stirring, etc. | |||||

Round bottles

Square bottles

Flat bottles

Tubes

Cream jars

Jar packaging

No need to replace complex molds, one machine to adapt to a variety of bottle types, improve flexibility.

1. 15 years of export experience serving customers worldwide

Products exported to the United States, Europe, Asia, many countries, reliable and stable.

2. Professional OEM / ODM Services

Available according to industry needs:

Special fill volume customization

double-head independent control customized

Hopper heating and stirring system

automatic convey line matching

3. Total Quality Inspection (QC)

All Double heads cream filling machines are subjected to:

Continuous operation test

accuracy test

air tightness test

health Laboratory

4. Full after-sales service (pre-sale → in-sale → after-sales)

Installation and Operation Videos Available

Remote Engineer Technical Support

Free wearing parts

Lifetime maintenance service

1. Will high viscosity paste block the filling nozzle?

Very well. No. the device adopt that design of a valve body with enlarged drift diameter, and meanwhile, the material

flow path is short and is not easy to block. Heated or mixing hoppers can be provided if required.

2. Is the fill volume stable? How much can the error control?

The accuracy can reach ±1%, which is far better than that of the common equipment of ±3 ‰ 5% on the market.

3. Is it easy to clean? Will refueling be slow?

It can be cleaned in 5 - 10 minutes by using quick release structure, which is suitable for various production.

4. Is customization supported?

Sammipack, as China Manufacturer Factory, offers:

Filling speed/fill volume customization

Double-head single metering system

Heat stirring hop

Automatic production line (filling + capping + labeling)

5. When will the shipment be ready?

Standard models are available in stock and can be shipped in 1 - 3 days. The custom flight will take about 5 - 12 days

according to the plan.

As a professional Manufacturer & Supplier of Double heads cream filling machine China, Sammipack offers you:

Free filling test

One-to-one selection scheme

Volume Purchase Offers

International Express Direct

Double heads cream filling machine is the ideal solution to solve the problems of low efficiency, large error, complicated cleaning and high labor cost in the factory. Whether you are from the food, cosmetic, pharmaceutical or daily chemical industries, Sammipack is your trusted China Factory Manufacturer with cost-effective equipment that fully meets industry standards.

For prices, videos or technical information, please feel free to contact us and we will provide professional purchasing support.